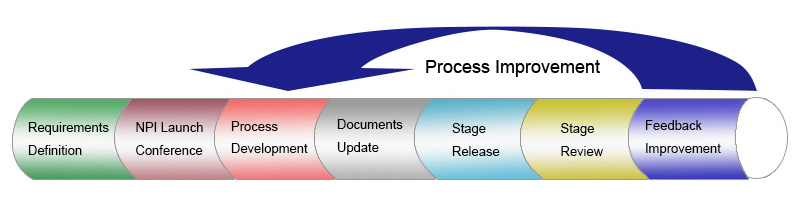

As an independent research and development manufacturing enterprise, it needs good cooperation in all aspects of market research, product design, trial production, mass production, delivery and customer service, to be able to respond to market demand efficiently and flexibly. To this end, Semu Electronics sorted out various related processes, carried out product demand definition, conceptual design and design verification process optimization, introduced the PLM management system to effectively manage the product development process, accumulated development knowledge and experience, and provided timely Provide more information to project team members, improve project team work efficiency, and provide greater value to customers and shareholders.

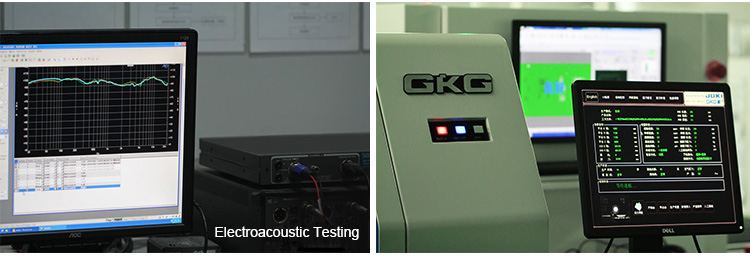

Based on years of testing experience in consumer electronic products, Semu Electronics designs a set of high-quality testing solutions based on customer product characteristics to ensure product quality compliance, reliability, stability and consumer satisfaction. Semu Electronics also attaches great importance to the construction of internal laboratories. It has a unique enterprise-level laboratory with excellent equipment, sufficient quantities, and comprehensive experimental equipment, such as constant temperature and humidity testing machines, salt spray testing machines, vibration testing machines, abrasion resistance testers, Baige testers, tensile testers, wire swing testers, battery capacity testers, flip testers, button life testers, ROHS testers, ESD electrostatic discharge testers, electroacoustic testers, etc. It can meet the test requirements of different customers.

Key factors of testing: product technical characteristics, product key indicators, appearance requirements, electrical characteristics, product application characteristics, reliability requirements, shipment requirements, product life cycle requirements, industry norms and standards, and historical data.

The main test items: Bluetooth test, aging test, product pressure test, mechanical test, climate test, audio test, software test, EE test, RF test, IQ test, etc.

In the design and development stage, NPI engineers will participate in the process of material selection, manufacturing feasibility analysis, and test plan design to ensure more accurate cost budget and control, lower defective products and waste, better risk prevention, and smoother operation for following mass production. And better and more stable product quality will ultimately enhance the efficiency and quality of product batch manufacturing, improve flexibility and shorten product launch time, and realize the optimal utilization of the supply chain and manufacturing system.

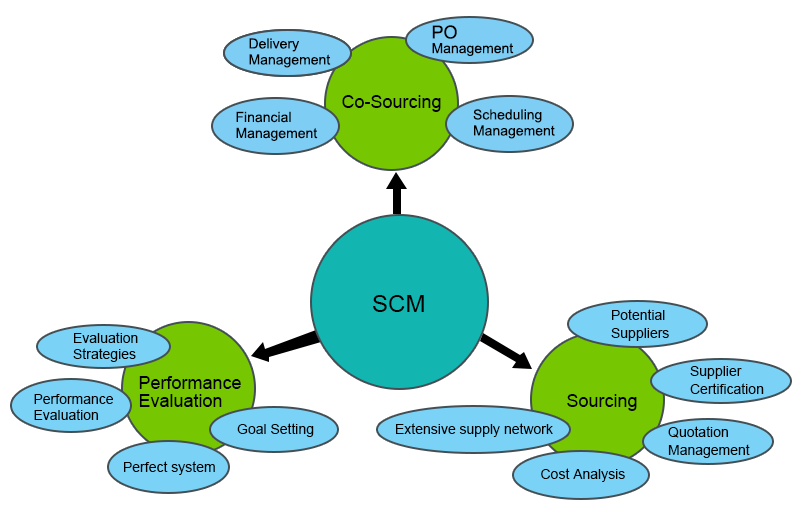

In order to improve supply efficiency and quality, and provide customer-satisfied service and quality, from supplier management, incoming material inspection, production process, reliability test, to shipment inspection system, Semu Electronics is based on a strict quality management system, continues to strengthen the management of the supply chain (material selection, material proofing, material review, material test approval, supplier on-site audit, improvement of missing problems, daily delivery quality control, annual routine audit, supplier assessment...), Optimize the operation process, reduce costs, and establish a good supply-demand relationship with suppliers, strengthen just-in-time procurement, and improve the response speed of the supply chain, so as to fully meet customer needs.

The injection molding workshop has more than 20 high-precision injection molding machines equipped with servo manipulators. It can be processed by molding and silk screen printing to meet various plastic molding processes.

Based on the strategic plan for the development of flexible manufacturing, Semu Electronics actively develops automation. Through the accumulation of technical modules, it can flexibly allocate resources and quickly implement production line deployment.

The SMT workshop realizes the full automatic production of multiple processes such as automatic double-track upper and lower boards, solder paste printing, SPI inspection, patch, reflow soldering, AOI inspection, board splitting, and FCT testing. It is specially equipped with the industry-leading Panasonic NPM double-track automatic placement machine imported from Japan, which can carry out high-speed and high-precision placement production, and at the same time can realize the placement of various components and fast model switching, greatly improving Improve production efficiency, quality and manufacturing flexibility.

The assembly and packaging workshop has introduced a series of single-station automated production equipment, including automatic ultrasonic and welding, automatic MTF focusing, automatic detection, automatic aging rack, automatic surface coating, heat shrinkable film for packaging boxes, automatic packaging, etc. Process, quickly improves production efficiency and product quality. At the same time, to meet the high-quality requirements of customers, the assembly workshop adopts a clean room as a whole, especially for the assembly of the lens/seat, an expensive 100-class dust-free workshop is used to ensure the cleanliness of the product. At the same time, it is equipped with an audio tuning room, and aging rooms.

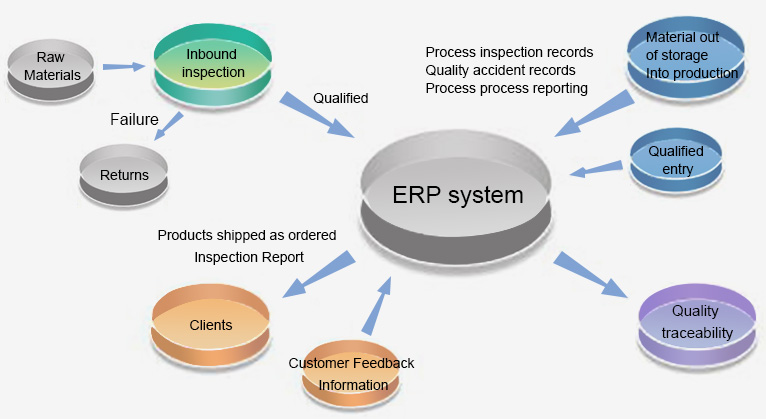

Over the years, Semu Electronics has always attached importance to the construction of information systems, and has successively introduced PLM, ERP, barcode traceability and other systems. From product planning to design and manufacturing, PLM can be used to manage the complete product design cycle, efficiently control the product life cycle, monitor and manage product design quality retrospectively, and ensure that all steps of product evolution are based on evidence. Active and traceable; through ERP, the logistics, capital flow, information flow and other resources of the enterprise are integrated and managed, and the cooperation between sales, planning, supply, manufacturing, and warehouses is strengthened to provide timely and accurate information feedback; the barcode traceability system is introduced, to effectively manage the product manufacturing process and after-sales service, to realize the whole process of product tracking from production, storage and transportation, sales and after-sales, and to trace the quality status and quality records of each product's production process according to the product barcode.